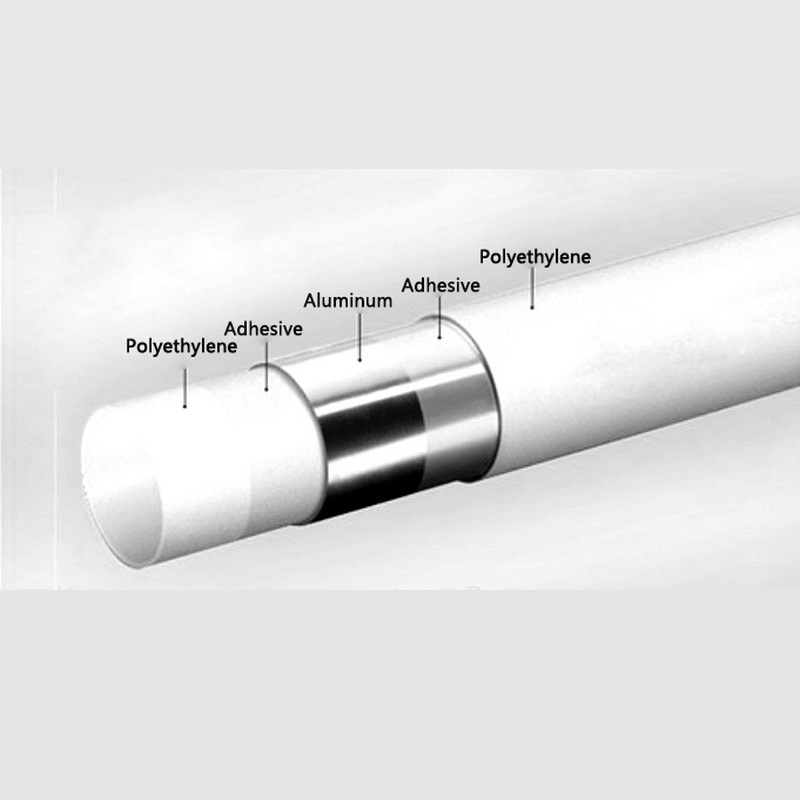

The linear molecular structure of polyethylene in aluminum strip for composite pex al pex pipe is transformed into a three-dimensional network structure by physical and chemical methods, thereby improving the performance of polyethylene.

Product specification

1. More resistant to aging and corrosion

2. More high-temperature resistance and low thermal conductivity

3. Stronger and more resistant to pressure and impact, easy to bend and not rebound

4. Under the same conditions, the water flow is larger than that of the metal pipe

5. High creep resistance, can be equipped with metal pipes, can save connecting pipe fittings, reduce installation costs, speed up installation cycle, and facilitate maintenance

6. Provides long-term protection against UV rays, extending its lifespan

| Aluminum Thickness | 0.150mm-0.5mm

(tolerance±0.02mm) |

| Aluminum Width | 20mm-600mm

(tolerance±0.4mm) |

| Inner Roll Diameter | 75mm/150mm |

| Alloy No. | 1050,1060,3003,3005,8006,8011 |

| Tensile Strength | EN-546 3003、8011、8006Rm (100MPa-130MPa) 1050 (80MPa-95MPa) |

| Elongation | EN546 (L0100≥20%) |

| Bend Strength | 3003、8011、8006Rp(60MPa-80MPa)1050Rp≥30Mpa |

| Surface | Mill Finishing |

PEX Pipe, multilayer pipe, composite al-plastic pipe, floor heating pipes

1. Indoor water supply pipes, hot water pipes, and pure water delivery pipes.

2. Liquid food transportation pipelines in the food industry.

3. Plumbing heating system, central air-conditioning piping system, ground radiant heating system, solar water heater system, etc.

4. telecommunications, electrical piping.

5. electroplating, petroleum, chemical plant pipeline system.