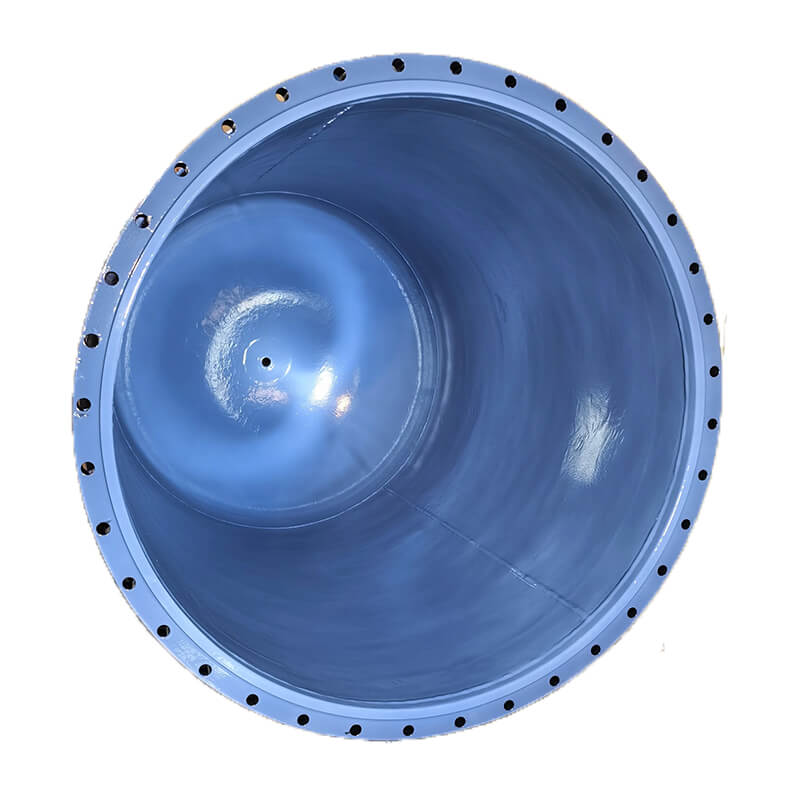

The Plastic lining equipment has advanced anti-corrosion processing technology that has been promoted abroad in recent years. The inner lining surface of the product is flat, smooth, and strong.

Product specification

Compared with the traditional steel-lined plastic plate storage tank, steel-lined rubber storage tank, and steel-lined FRP storage tank, it has better corrosion resistance, no leakage, no peeling, wear resistance, high-temperature resistance, longer life, etc.

In addition, the price is lower than the traditional storage tank of the same specification. Therefore, Plastic lining equipment is an ideal container for storing corrosive liquids.

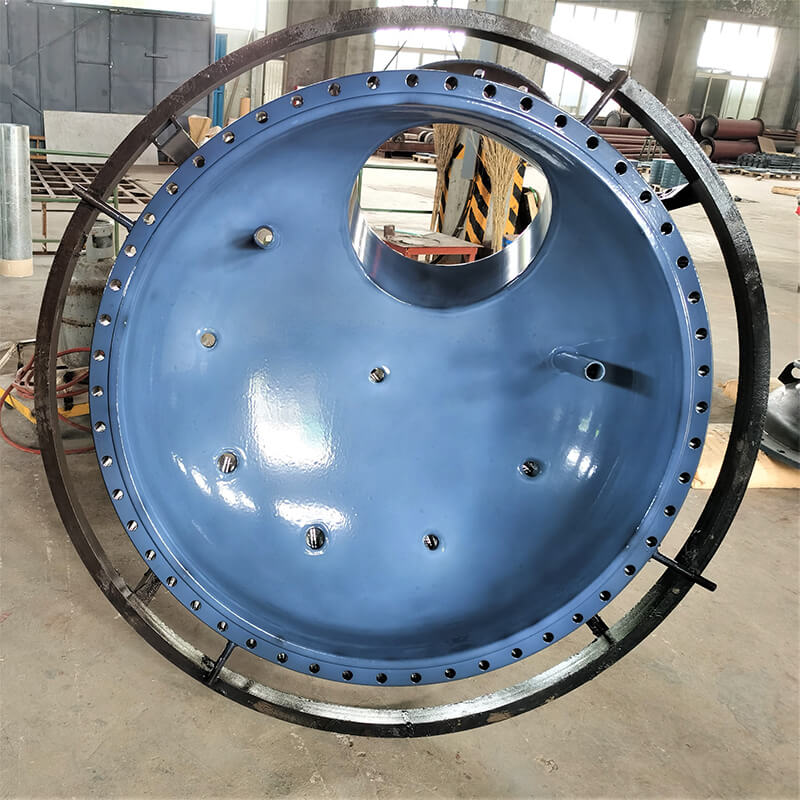

Materials:

·Carbon steel

·Stainless steel

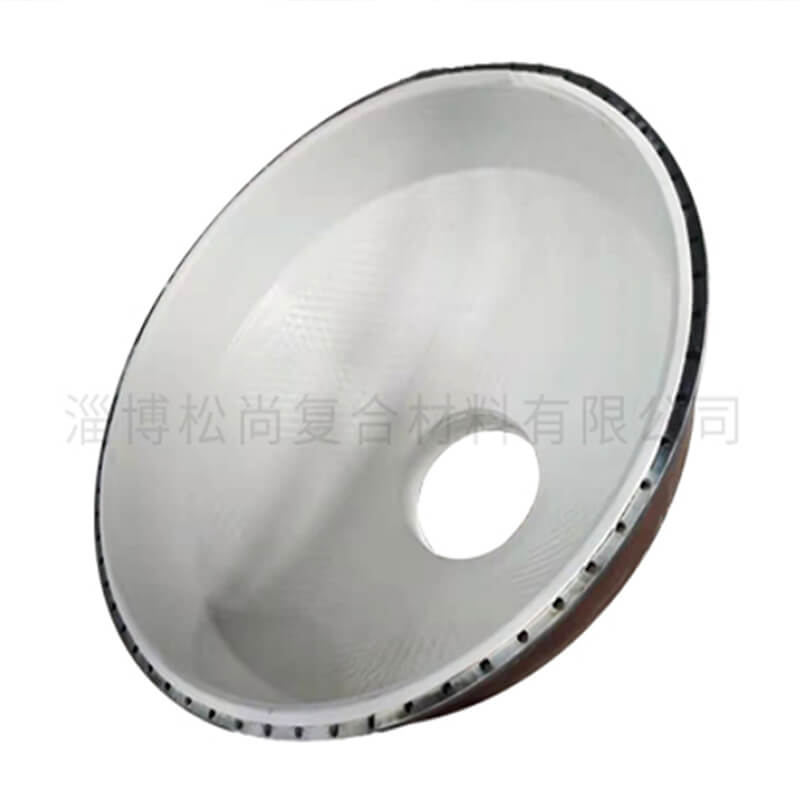

Lined method:

·Spray Lining, Roller Coating, Extrusion

Lined materials:

·F40/F30/PFA/FEP(spray lining)

·F40/F30/ETFE /PO/PP/PE (roller coating)

·PTFE/PFA/PVDF(extrusion)

Applicable medium:

·Concentrated hydrochloric acid, hydrofluoric acid, sulfuric acid, nitric acid, phosphoric acid. Acetic acid, caustic soda, sodium hypochlorite, naphthalene, benzene, xylene, acetone, chlorine, toluene, various organic solvents, etc.

Corrosive liquid storage, metering tank, suction filter barrel, desalination pretreatment equipment, anti-corrosion layer of ion exchange equipment.