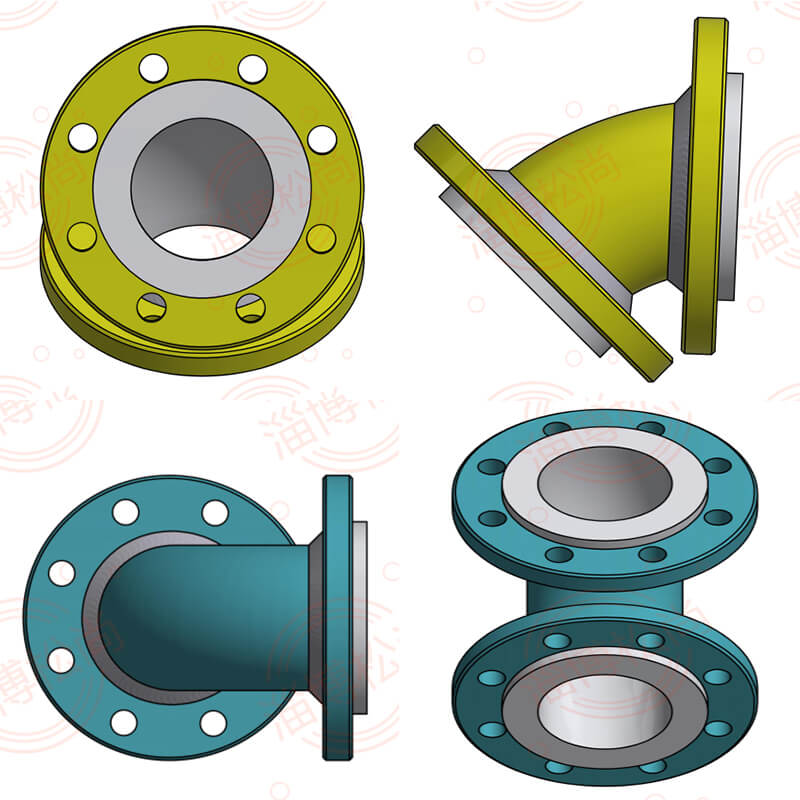

The PTFE-lined elbows supplied by Songshang are in 45°and 90°commonly. And we can manufacture 30°and 60°elbows or other degree elbows in specific dimensions required to make sure the perfect flow.

Product specification

The manufacturing process used in the PTFE-lined elbows is molding. Compared with the extrusion method, it is a processing method that is more resistant to positive and negative pressure, high temperature, and strong corrosion.

The flanges on PTFE-lined elbows can be connected in fix-loose/loose-loose/fix-fix.

Materials:

·Carbon steel

·Stainless steel

Lined Materials:

·PTFE F4 (Virgin or anti-static*)

·PFA FA (Virgin or anti-static*)

·ETFE F40

·FEP F46

·* Conductive black PTFE or PFA

Flange Dimensions:

·ASME B16.5 Class 150, can be customized

Flange Options:

·HG, GB, JB, JIS, BS, DIN, ANSI, ASTM

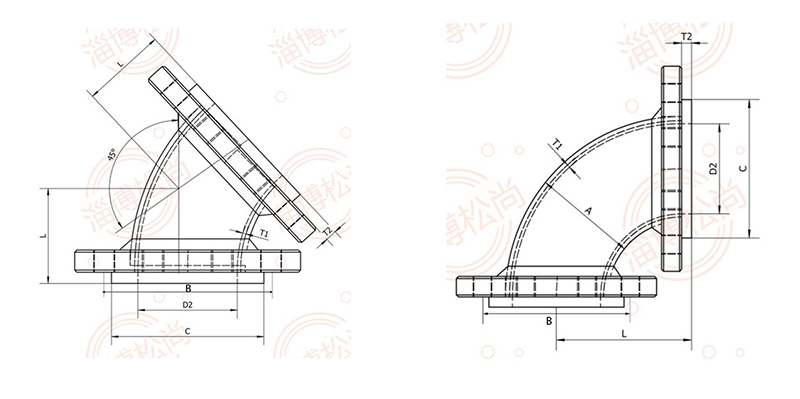

| Nominal Diameter | Molding Shell(A) | Flanging Face Diameter(C) | Inside Diameter(D2) | PTFE Thickness (Neg.Pressure)(T1) | PTFE Thickness (Isobaric) (T1) | Flanging Face Thickness(T2) | Diameter of bolt circle(B) | Elbows Central Height(L) | |

| DN(mm) | NPS(inch) | ||||||||

| DN25 | 1 | Φ42*3 | 60 | 24±0.5 | 4~4.5 | 3. 5~4.5 | 2 | 85 | 90 |

| DN32 | 1 ¼ | Φ45*3 | 70 | 32±0.5 | 4~4.5 | 3. 5~4.5 | 2 | 100 | 100 |

| DN40 | 1 ½ | Φ57*3 | 80 | 34±0.5 | 4~5 | 4~5 | 2.5 | 110 | 110 |

| DN50 | 2 | Φ68*3.5 | 95 | 45±0.5 | 4~5 | 4~5 | 2.5 | 125 | 120 |

| DN65 | 2 ½ | Φ76/89*4 | 115 | 63±0.5 | 5~7 | 5~6 | 2.5 | 145 | 130 |

| DN80 | 3 | Φ89/102*4 | 130 | 75±0.5 | 6~8 | 5~7 | 3 | 160 | 140 |

| DN100 | 4 | Φ108/114*4 | 150 | 94±0.5 | 6~8 | 6~8 | 3 | 180 | 150 |

| DN125 | 5 | Φ133*4/140*5 | 180 | 117±0.5 | 7~9 | 7~9 | 3.5 | 210 | 180 |

| DN150 | 6 | Φ159/168*4.5 | 205 | 141±0.5 | 8~10 | 7~9 | 4 | 240 | 200 |

| DN200 | 8 | Φ219*6.5 | 165 | 198±0.5 | 9~11 | 8~10 | 4 | 295 | 230 |

| DN250 | 10 | Φ273*7 | 320 | 247±0.5 | 10~12 | 8~10 | 5 | 350 | 250 |

| DN300 | 12 | Φ325*8 | 365 | 299±0.5 | 10~12 | 9~11 | 5 | 400 | 320 |