The Silicon Carbide Shell & Tube Heat Exchanger is an energy-saving device that realizes heat transfer between materials of different temperatures, which is able to improve energy utilization.

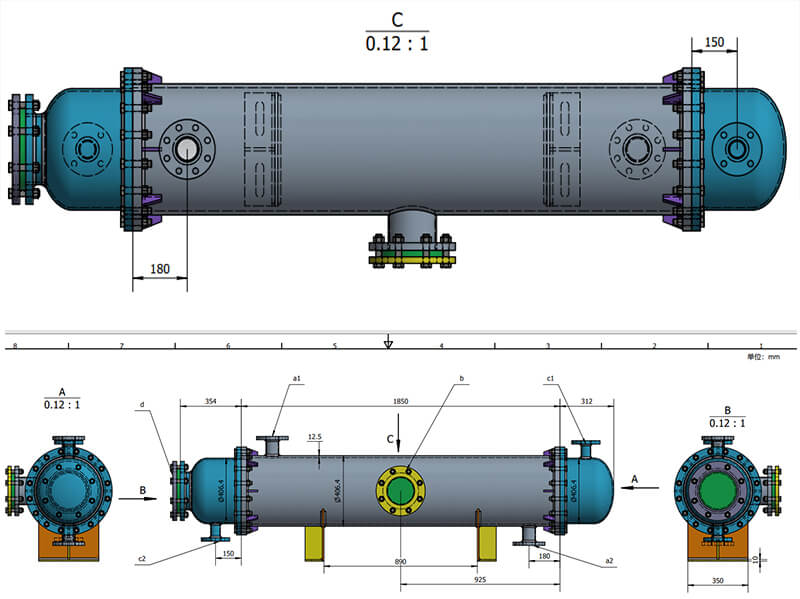

Product specification

Songang’s heat exchanger is a new type of heat exchanger that uses silicon carbide ceramic material as a heat transfer medium. Silicon carbide ceramics have excellent characteristics and it has brought numerious advantages to heat exchanger, such as highest corrosion resistance against acids, leaches, halogen compounds and oxidizing media, excellent thermal conductivity, best abrasion resistance, high resistance against thermal shocks, highest purity with no contamination, condensation on both shell and tube side, optimized tube sheet with low cost and compact design, no corrosion and leakage risk abd completely drainable.

Nominal diameter: DN100 – DN400

Length:1m – 4.5m

Operating pressure:-1bar – +6(+10)bar

Operating temperature:-10(-30)℃ – 180(220)℃

Heat transfer area:0.4㎡ – 42 ㎡

Shell material: Carbon steel/stainless steel/glass-lined

Head material:Carbon steel/stainless steel/glass-lined/PTFE-lined

Lined material: PTFE、PFA

Liquid/liquid heat transfer at acids, caustic media, and all kinds of organics, e.g. acid mixtures, sulphuric acid, nitric acid

Condensation processes

Condenser units including main and trap condenser and condensate cooler

Cooling of gases even with elementary halogen compounds (dry and moist)

High purity chemical processes and API manufacturing in the final stages

Acid concentration