PTFE Hose/PTFE Spiral Hoses with flanges and wire braid

The PTFE Spiral Hoses with flanges and wire braid can make up for the axial or radial error on installation, and they can solve the problem of expansion and contraction caused by climate change at the same time.

Product specification

The advantages of PTFE Spiral Hoses with flanges and wire braid include large compensation amount, excellent mechanical performance, good corrosion resistance, long service life, etc.

As a vibration damper, it is installed at the inlet and outlet of the pump or both ends of other high-frequency vibration machines to reduce vibration, which can improve the service life and sealing performance of the pipeline.

Nominal Diameter:

·DN25-DN600

Operating Temperature:

·-50℃~250℃

Operating Pressure:

·-0.05-2.5MPa

Materials:

·Carbon steel

·Stainless steel

Lined Materials:

·Virgin or anti-static* PTFE F4

·Virgin or anti-static* PFA (perfluoroalkoxy) FA FEP F46

·*Conductive black PTFE or PFA

Flange Dimensions:

·ASME B16.5 Class 150

Flange Options:

·HG, GB, JB, JIS, BS, DIN, ANSI, ASTM

Applicable medium:

·Concentrated hydrochloric acid, hydrofluoric acid, sulfuric acid, nitric acid, phosphoric acid. Acetic acid, caustic soda, sodium hypochlorite, naphthalene, benzene, xylene, acetone, chlorine, toluene, various organic solvents, etc.

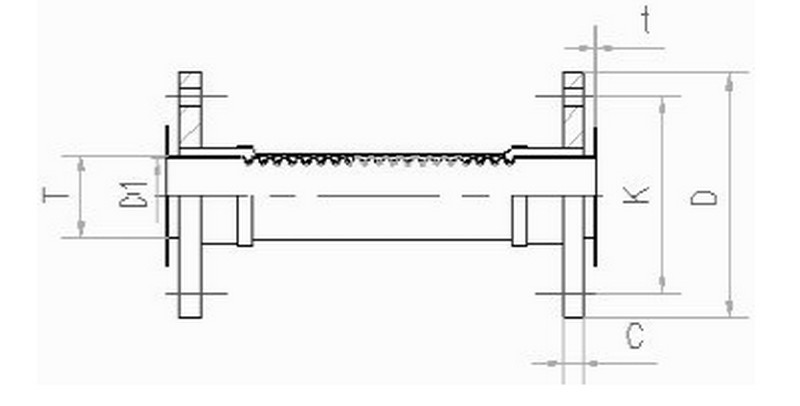

| Nominal Diameter | PTFE diameter(T) | Inside diameter(D1) | Flange diameter(D) | Diameter of bolt circle(K) | Flange thickness(C) | |

| DN(mm) | NPS(inch) | |||||

| DN15 | ½ | 22*1.5 | 19 | 90±0.5 | 65±1 | 11 |

| DN20 | ¾ | 22*1.5 | 19 | 100±0.5 | 75±1 | 11 |

| DN25 | 1 | 25*2 | 21 | 110±0.5 | 85±1 | 12 |

| DN32 | 1 ¼ | 32*2 | 28 | 130±1 | 100±1 | 13 |

| DN40 | 1 ½ | 40*2 | 38 | 140±1 | 110±1 | 14 |

| DN50 | 2 | 52*2 | 48 | 155±1 | 125±1 | 14 |

| DN65 | 2 ½ | 64*2 | 60 | 175±1 | 145±1 | 16 |

| DN80 | 3 | 78*2 | 74 | 190±1 | 160±1 | 16 |

| DN100 | 4 | 100*2.2 | 95 | 210±1.5 | 180±1 | 18 |

| DN125 | 5 | 126*2.5 | 121 | 240±1.5 | 210±1 | 20 |

| DN150 | 6 | 150*2.6 | 145 | 275±1.5 | 240±1 | 20 |

| DN200 | 8 | 200*2.8 | 194 | 330±1.5 | 295±1 | 20 |

| DN250 | 10 | 250*3.5 | 243 | 385±1.5 | 350±1 | 23 |

| DN300 | 12 | 300*3.8 | 292 | 435±1.5 | 400 | 23 |