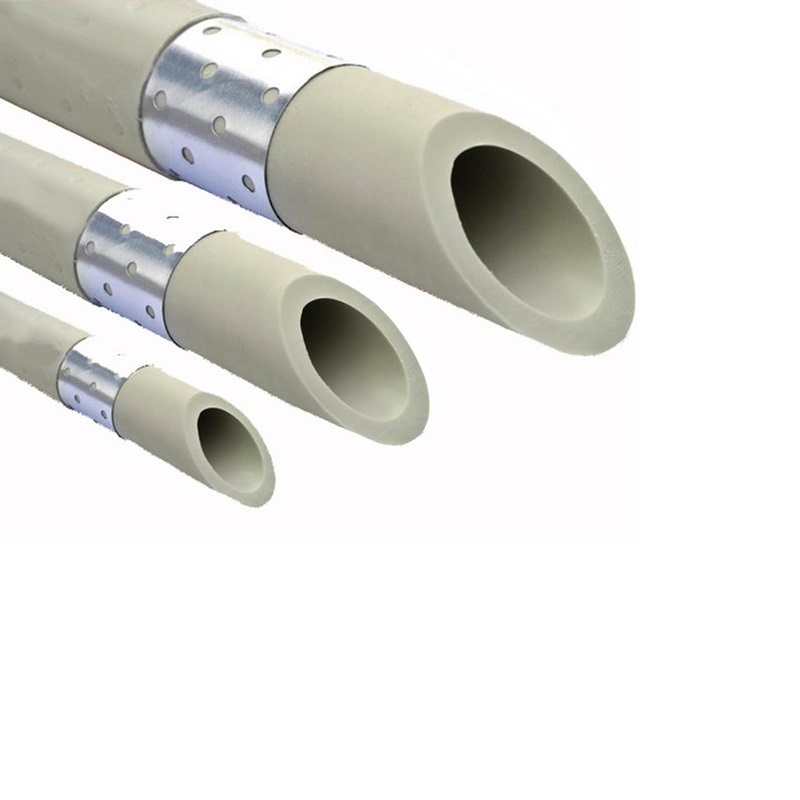

Perforated Aluminum Strip for PP-R Steady-state Tube

Using hot melt bonding technology, the outer surface is organically bonded to the aluminum tape with a thickness of 0.15/0.12mm at high temperatures. Perforated Aluminum Strip for PP-R.

Steady-state Tube has a five-layer structure of polypropylene-glue-aluminum-glue-polypropylene, and the middle aluminum layer plays a reinforcing role, which organically combines PP-R plastic and metal and keeps the flexibility of plastic pipe and the rigidity of metal pipe.

Product specification

1. Small coefficient of linear expansion, high-temperature resistance, no deformation

2. Impermeable to oxygen, can inhibit the growth of algae bacteria, more hygienic

3. Aluminum layer can effectively block UV rays and have a longer service life

4. The aluminum layer is more pressure-resistant and stable for the pipeline and reduces creep.

5. Hot melt connection, no leakage

| Aluminum Thickness

|

0.150mm/0.120mm

(tolerance±0.02mm) |

| Aluminum Width

|

Max 600mm

(tolerance±0.4mm) |

| Roll length | 1300m~2600m |

| Inner Roll Diameter | 150mm—152mm |

| Alloy No. | 3005、3003、8011 |

| Coating Thickness/each side | 0.04mm、0.05mm |

| Coating method | Single Side/Double Side |

| Coating Material | Polypropylene |

| Tensile strength | 120-165N/mm |

| Peel Strength | ≥6N/15mm |

| Elongation | EN546(≥12%) |

| Vickers Hardness | 20-27 |

| Resin Binder | QF551/MITSUI |

| Hole Diameter | 2.5mm |

Solar energy, thermal energy, central air conditioning system, heating system, high-temperature hot water, outdoor surface installation, etc.