PTFE rod is made of PTFE resin and manufactured by molding or ram extrusion method. Among the known plastics, PTFE has the best chemical corrosion resistance and dielectric properties, can be used at temperatures from -180°C to +260°C, and has the lowest coefficient of friction.

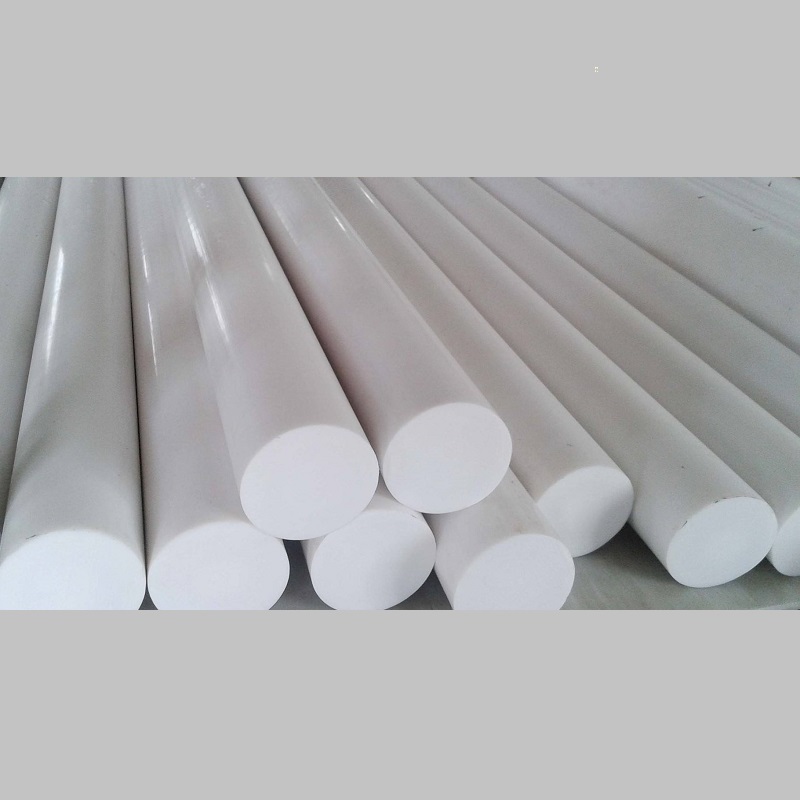

Product specification

It is mainly suitable for some long products and non-standard products. Specifications of mechanical parts: seals/gaskets, rings, wear plates/seats, insulation parts, anti-corrosion industries, mechanical parts, linings, oil and gas, petrochemical industries, chemical industries, instrument and equipment manufacturers, etc.

High and low temperature resistance (-192 ℃-260 ℃),

Corrosion resistance (strong acid, strong alkali, aqua regia, etc.)

Weather resistance

High insulation

High lubrication

Non-adhesion

Non-toxic

| Nominal Diameter | Length | |

| Molding method | 10-300 | 1-300 |

| Paste Extrusion | 5-250 | As needed |

Other dimensions can be supplied on request

Chemical industry: It can be used as an anti-corrosion material and can manufacture various anti-corrosion parts, such as pipes, valves, pumps, and pipe fittings. In terms of chemical equipment, it can be used to make linings and coatings for reactors, distillation towers, and anti-corrosion equipment.

Mechanical: It can be used as a self-lubricating bearing, piston ring, oil seal and sealing ring, etc. Self-lubrication can reduce the wear and heat of parts and reduce power consumption.

Electronic appliances: mainly used in the manufacture of various wires and cables, battery electrodes, battery separators, printed circuit boards, etc.

Medical materials: Utilizing its heat-resistant, water-resistant, and non-toxic properties, it can be used as a material for various medical devices and artificial organs. The former such as sterile filters, beakers, artificial heart-lung devices, the latter such as artificial blood vessels, heart, and esophagus. It has been widely used as sealing material and filling material.