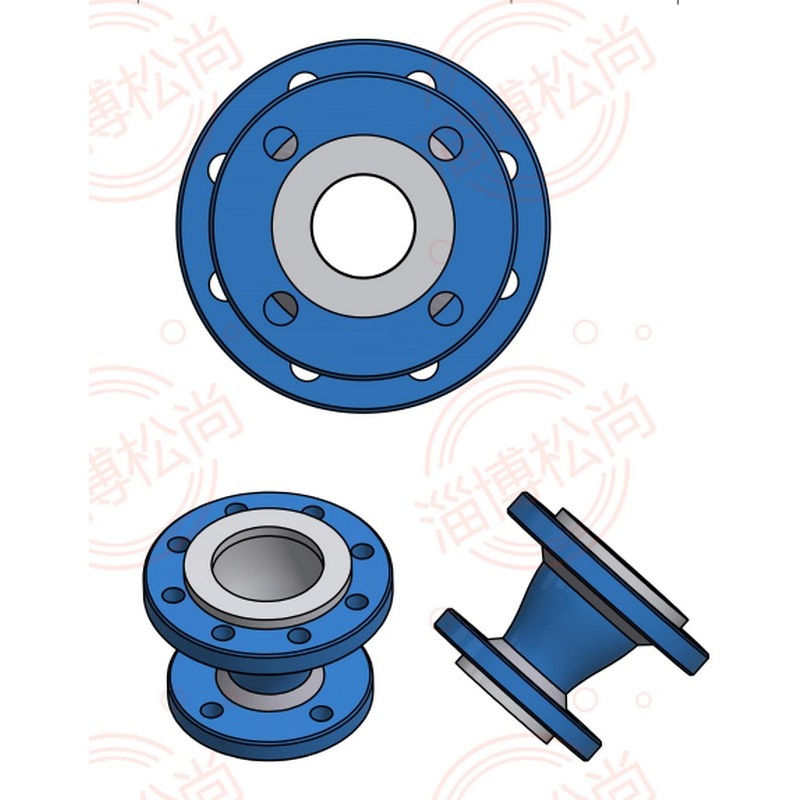

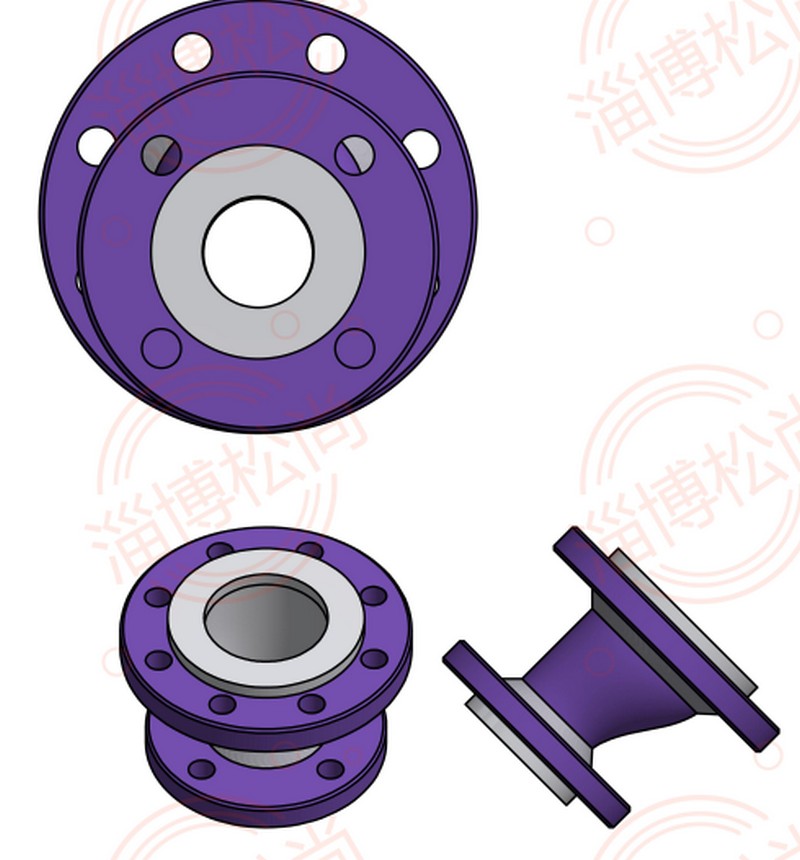

The PTFE lined reducer can be manufactured as a concentric or eccentric reducer on request to meet different requirements of connection and installation under various using conditions.

Our common reducer made is with fixed flanges, which is more economical, and other welding types like loose-fix and loose-loose are available as well.

Product specification

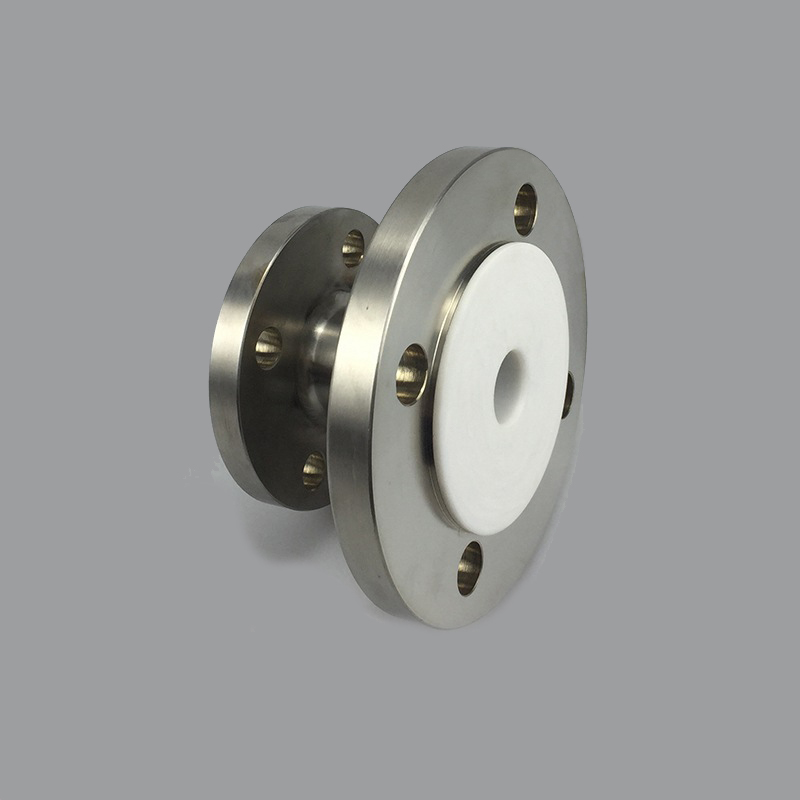

Materials:

·Carbon steel

·Stainless steel

Lined Materials:

·PTFE F4 (Virgin or anti-static*)

·PFA FA (Virgin or anti-static*)

·ETFE F40

·FEP F46

·*Conductive black PTFE or PFA

Flange Dimensions:

·ASME B16.5 Class 150, can be customized

Flange Options:

·HG, GB, JB, JIS, BS, DIN, ANSI, ASTM

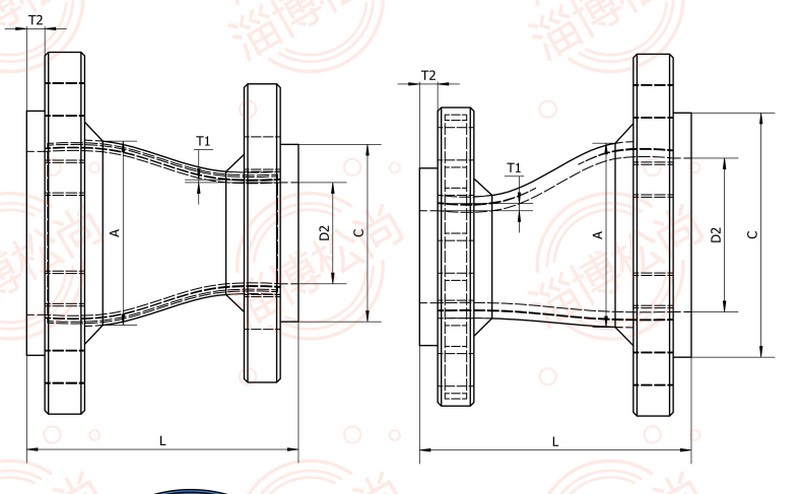

| Nominal Diameter | Seamless pipes for straight pipe(A) | PTFE Tube | Flanging Face Diameter(C) | Inside Diameter(D2) | PTFE Thickness (Neg.Pressure)(T1) | PTFE Thickness (Isobaric) (T1) | Flanging Face Thickness(T2) | Length MAX(L) | |

| DN(mm) | NPS(inch) | ||||||||

| DN25 | 1 | Φ32*3 | Φ26*3 | 60 | 24±0.5 | 4~4.5 | 3. 5~4.5 | 2 | 150 |

| DN32 | 1 ¼ | Φ38*3 | Φ32*3 | 70 | 32±0.5 | 4~4.5 | 3. 5~4.5 | 2 | 150 |

| DN40 | 1 ½ | Φ45*3 | Φ39*3 | 80 | 34±0.5 | 4~5 | 4~5 | 2.5 | 150 |

| DN50 | 2 | Φ57*3 | Φ51*3 | 95 | 45±0.5 | 4~5 | 4~5 | 2.5 | 150 |

| DN65 | 2 ½ | Φ76*4 | Φ68*3 | 115 | 63±0.5 | 5~7 | 5~6 | 2.5 | 180 |

| DN80 | 3 | Φ89*4 | Φ81*3 | 130 | 75±0.5 | 6~8 | 5~7 | 3 | 180 |

| DN100 | 4 | Φ108*4 | Φ100*3 | 150 | 94±0.5 | 6~8 | 6~8 | 3 | 180 |

| DN125 | 5 | Φ133*4 | Φ125*3 | 180 | 117±0.5 | 7~9 | 7~9 | 3.5 | 180 |

| DN150 | 6 | Φ159*4. 5 | Φ150*3 | 205 | 141±0.5 | 8~10 | 7~9 | 4 | 180 |

| DN200 | 8 | Φ219*6 | Φ206*4 | 165 | 198±0.5 | 9~11 | 8~10 | 4 | 180 |

| DN250 | 10 | Φ273*7 | Φ255*5 | 320 | 247±0.5 | 10~12 | 8~10 | 5 | 200 |

| DN300 | 12 | Φ325*8 | Φ306*5 | 365 | 299±0.5 | 10~12 | 9~11 | 5 | 200 |