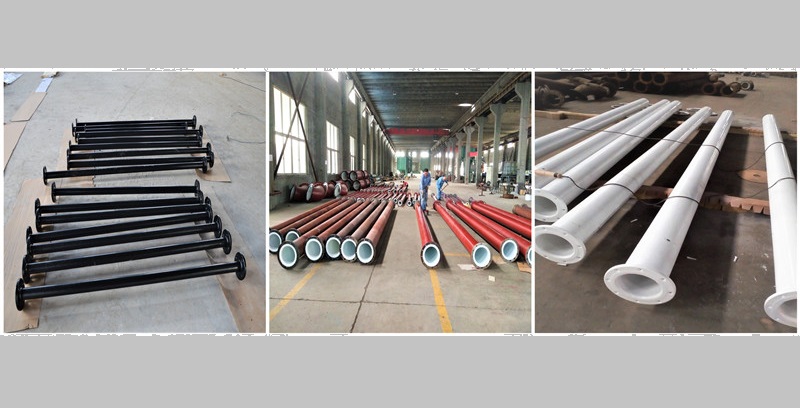

The steel-lined pipe is based on carbon steel pipe and is lined with different plastics with excellent chemical stability, which can meet different purposes of usage. The main products of lined pipes that Songshang manufactured include steel-lined PO/PE/PP/PTFE composite pipes.

Performance:

Medium working temperature: -25℃~+105℃

Medium working pressure: positive pressure 2.5MPa; negative pressure 90KPa

Product features: non-toxic, temperature resistance, low temperature resistance, negative pressure resistance, vacuum corrosion resistance, aging resistance, impact resistance , the surface is smooth and the bonding force is strong. It has good performance for organic solvents of general acid and alkali salts, and is suitable for the transportation of corrosive gas, liquid and solid liquid, and slurry medium.

Typical application: This product is widely used in chemical, biological, electric power, smelting, pharmaceutical, food, environmental protection, and other fields. It is an ideal material to replace rubber porcelain, glass fiber reinforced plastic, stainless steel, and plastic plate linings within -20℃-105℃.

Particularity: PO: anti-corrosion, anti-static, non-toxic, high strength; PE: resistant to a variety of organic solvents, resistant to a variety of acid and alkali corrosion, but not resistant to oxidative acids, such as nitric acid. In an oxidizing environment, PE will be oxidation.

Performance:

Medium working temperature: -25℃~+110℃;

Medium working pressure: positive pressure -25MPa, negative pressure at room temperature is 94Pa

Typical application: It is suitable for the transportation of corrosive fluid media and industrial pure water, chemical pure water, ionized water, and non-ionized water. Its service life is longer than that of stainless steel. It can replace stainless steel pipes. long.

Corrosion resistance: In addition to strong oxidizing acids such as concentrated nitric acid, fuming sulfuric acid, and chlorosulfonic acid, it is resistant to most organic and inorganic acids, alkalis, and salts. It has good corrosion resistance to stress corrosion and can withstand nitric acid below 10%. , formic acid, acetic acid, hydrochloric acid below 36%, hydrobromic acid below 20%, dilute hydrofluoric acid, various concentrations of carbonic acid, boric acid, butyric acid, alkali and most salts, mercury, air, NH3, CO2, Corrosion of CO, NO2, HCL and other gases is multifunctional. Large-scale steel-plastic composite pipe machine production, one-time forming element according to the seam, authentic lining technology, smooth and firm and never fall off. Widely used in petrochemical products, food environmental protection, electric power and other fields.

Polytetrafluoroethylene (English abbreviation is Teflon or [PTFE, F4]), is known as/commonly known as “Plastic King”.

It is a polymer compound formed by the polymerization of tetrafluoroethylene, with excellent chemical stability and corrosion resistance (it is one of the best corrosion resistance materials in the world today, in addition to molten metal sodium and liquid fluorine, it is resistant to other All chemicals do not change even when boiled in aqua regia, and are widely used in various applications that require resistance to acid, alkali and organic solvents), sealing, high lubrication and non-stick properties, electrical insulation, good anti-aging endurance, and excellent temperature resistance ( It can work for a long time at the temperature of +250℃ to -180℃).

Properties:

Low-temperature resistance – good mechanical toughness; 5% elongation can be maintained even when the temperature drops to -196°C.

Corrosion Resistance – Inert to most chemicals and solvents, strong acid and alkali resistance, water and various organic solvents.

Weather Resistant – Has the best aging life of any plastic.

High Lubrication—The lowest coefficient of friction of any solid material.

Non-stick — is the smallest surface tension in a solid material that does not stick to anything.

Non-toxic – It is physiologically inert, and it has no adverse reactions when it is implanted in the body as artificial blood vessels and organs for a long time.